Programming the

OWI-007

Robot Arm

Background:

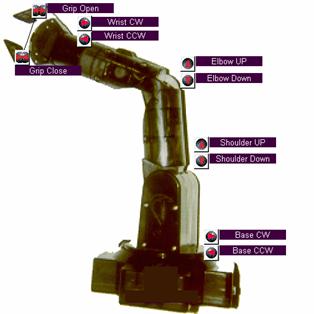

The

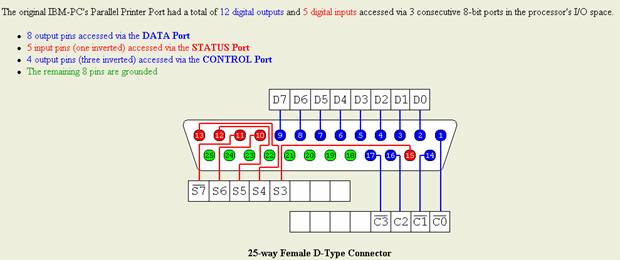

Figure 1[1]

The Robot Arm uses pins D0..D7 on the parallel port to turn on and off motors for the robot. The bit pattern required to make each individual move is in Table 1 below.

Port Numbers

There are three different addresses commonly used for the parallel port. These are 278h, 378h and 3BCh (h -> hex). You must determine the address used by YOUR COMPUTER. This can be done by looking at the LPT1 settings under the device manager (or on some computers it comes up when the computer is booting). In windows you might see something like this:

Figure 2 –

The range 0278-27B is the

Windows and

Sometimes the Windows Operating system does not like to give up control of the printer port. Since I usually have students program the robot in Assembly Language and run the program on a DOS based machine, this is not a problem for me, but if the arm is not acting as predicted, this MIGHT be the problem so I warn you here.

Thinks to keep in

mind when programming

- The robot will only one axis at a time.

- The robot will only move from the time the data is sent to the port till you send the next value to the port. Most of the time, this means you will need some kind of delay before sending the next value to the port.

- If you end your program with the arm in motion, the robot will continue to move after the program ends. Always send the stop signal before ending your program

- When restarting the computer, turn off the robot arm or it will start moving. I put a “PRESS ANY KEY” routine in the program and when I get the message, I turn the robot arm on.

Making the Robot Move

To make the robot do each move, you must send the proper number (from Table 1) to the printer port. Most software languages have a command to send a value to a hardware port or address. I have listed some of the languages I am familiar with below along with some tips on the commands to use.

Intel Assembly

Language

To write a bit pattern to these pins you have to use the OUT

op code. The address for the port MUST be in register DX. The value to write to

the port must be in

Mov dx,378h

Mov al,value_to_write

Out dx,al

So if we want to open the gripper we would have to do the following commands:

Mov dx,378h ;Write to LPT1

Mov al,0000_1111b ;the value to open the gripper

Out dx,al

LabVIEW

The robot can be programmed via LabVIEW. See http://zone.ni.com/devzone/conceptd.nsf/webmain/72C6FC6CE4AD4D1386256B1800794596

Qbasic

You can program the robot arm in this language as well. The OUT instruction can be used. You will need to convert the HEX value of the port to a DECIMAL number. Refer to your QBASIC Manual for more info on the command.

C

I have not programmed the robot arm using C, but it looks like it can be done using the outb() instruction. See http://www.faqs.org/docs/Linux-mini/IO-Port-Programming.html

Visual Basic 6.0

To gain direct control of the parallel port in VB 6.0 you need to add a special DLL. I suggest reading: http://www.lvr.com/parport.htm#Programming

Figure 3[2]

Table 1:

|

Joint |

Motion |

Binary Output |

|

Gripper |

Open |

0000_1111b |

|

|

Close |

0000_0000b |

|

Wrist |

CW |

0000_0100b |

|

|

CCW |

1000_0111b |

|

Elbow |

Up |

0001_0111b |

|

|

Down |

0000_0001b |

|

Shoulder |

Up |

0000_0011b |

|

|

Down |

0100_0111b |

|

Base |

CW |

0010_0111b |

|

|

CCW |

0000_0010b |

|

STOP |

|

0000_0111b |